High Quality Cast Iron and SG Iron Foundry Certified By Global Standards

High Quality Cast Iron and SG Iron Foundry Certified By Global Standards

Yash Metallics Pvt. Ltd.

Single source supplier for major automobile OEMs across India for flywheels and bearing caps

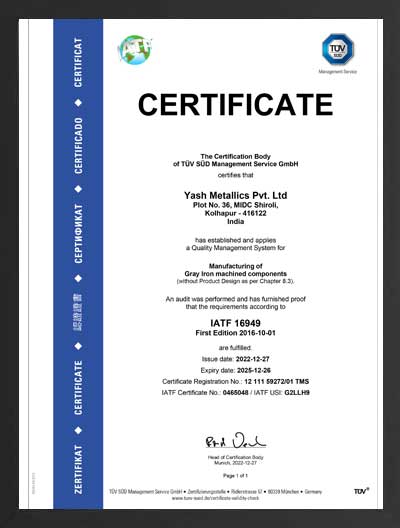

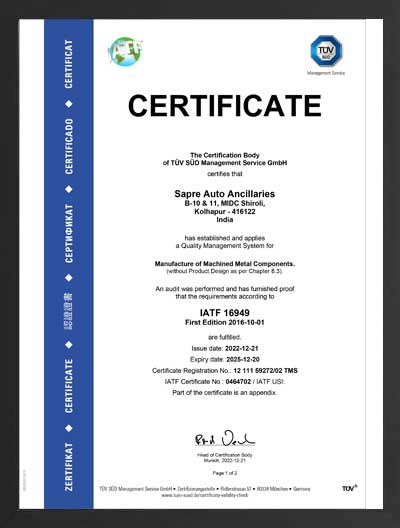

We at Yash Metallics Pvt Ltd, produce Cast Iron as well as Ductile Iron to cater all major OEMs in India. We are IATF 16949-2016, ISO 9001:2015, ISO 14001:2015 (EMS) and ISO 45001:2018 (OHSAS) certified company. YMPL has an integrated facility with all under one roof – foundry, machining, painting & sub-assembly. YMPL has per month 2000 MT good casting capacity with 3 Induction furnaces having capacity of 1000 Kg each. We are single source supplier for major OEMs across India. YMPL is one of the largest manufactures of flywheels, rear axcle carriers, housings, oil pump bodies, pulleys, adapters and bearing caps. We provide major parts to renowned OEMs like Mahindra & Mahindra, Volvo Eicher Commercial Vehicle, Daimler India Pvt.Ltd., Caterpillar, Qualitas Exports etc.

Our Foundry Capability

Material

Cast Iron

SG Iron (Ductile)

Casting Range

Weight: 1 kg to 55 kg

Values

Machining

Sub-assembly

Annual Volume

60,000 finished Flywheel Casting per month

24,000 MT Castings per year

29+

Years of

Experience

60000

Flywheel Castings

Per Month

24000

Metric Ton Castings

Per Year

55 kg

Max Casting

Weight

Components We Manufactured

Castings & machined components manufactured by us with utmost precision

Why Choose Us?

Manufacturing Excellence

Sophisticated manufacturing and testing capabilities provide great mileage in fulfilling customer needs

Skilled Manpower

We have vibrant workforce comprising highly qualified professionals and highly skilled and experienced workmen

Robust QMS

Our QMS adheres to ISO 9001:2015, IATF 16949:2016, ISO 14001:2015 (EMS) and ISO 45001:2018 (OHSAS). Product Quality & Satisfied customers are the result of our QMS culture

Customer First Approach

We make every decision and measure every outcome based on how well it serves our customers

Fast Component Development

Our team has the experience and the proficiency for quicker development with optimum lead time

Flexibility in Manufacturing

Our facilities are designed to meet variable requirements in terms of size, weight, criticality and grades